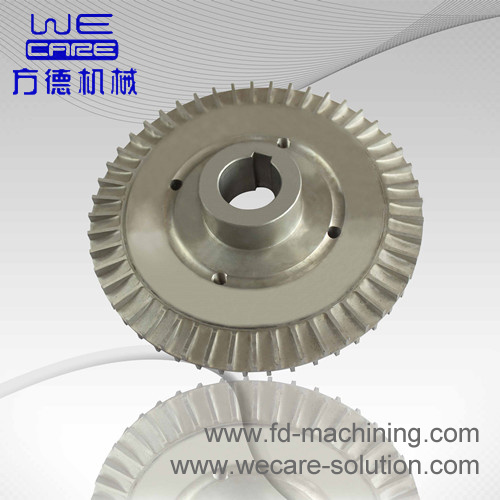

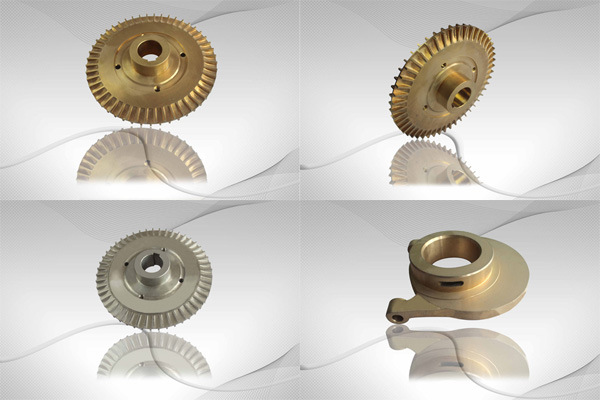

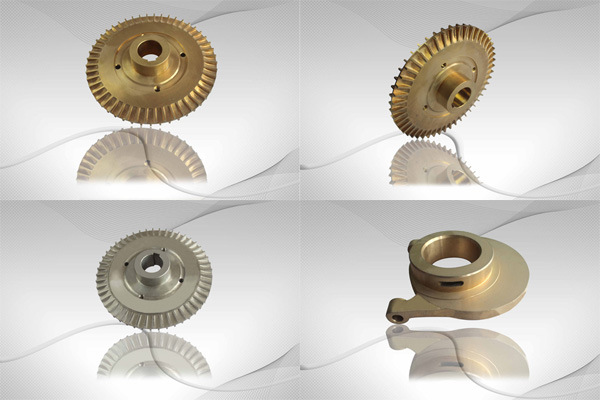

High Quality Investment Casting-Bearing Seat For Auto Parts Machining Parts1. Process of aluminum die casting part: Die casting + complete machining + heat treatment + surface treatment

2. Aluminum die casting mold Material: 8407, H13, P20, etc. Aluminum die casting mold Life: >1, 000, 000 times, Aluminum die casting mold Design: According to Drawing or Sample.

3. Aluminum die casting accessory material: Aluminum Alloy A380 or as customer's requirement.

Aluminum Die casting is especially suited to production of large quantities of relatively small parts. The more important reasons for using light metal casting are low weight, mechanical strength, stiffness and electrical properties. Other applications are e. G. Components for the power transmission line in the vehicle industry and electronics industry.

Wecare Precision Cast Parts uses this process exclusively. Wax is injected into an aluminum die to create a wax "pattern". These wax patterns are then assembled onto a "tree" which is repeatedly dipped in a ceramic slurry that, after drying, hardens into a mold. The wax is melted out, the mold is preheated and the metal is poured in. The resulting casting has an excellent surface finish of around 125 RMS, crisp lettering and minimal machine stock. This process is perfect for highly visible or highly machined parts. Tolerances can be held to +/-. 005" in most cases.

Advantages: Excellent overall appearance, machining reduced or eliminated, can cast very thin walls, good for prototypes, economical tooling costs.| Material available | Carbon steel, Stainless steel, spring steel, Bronze, brass, copper alloy, aluminum alloy, tinplate, nickel silver, plastic |

| Surface treatment available | Zinc/Nickel/Chrome Plating(color or natural), Galvanization, Anodizing, Hard Anodizing, Oil Spraying, Powder Coating, Polishing, Passivate, Brush, Wire drawing, etc. |

Manufacturing

Methods | Investment Casting, Die Casting, Sand Casting, Stamping, CNC Machining, Forging, |

| Specification | OEM & make per customer' s drawing or sample |

| Package | According to customer' s requirement; |

| Tolerance | CNC machining parts: +/-0.002 |

| Service available | We supply pre-production samples for customer final confirmation before mass production; |

| Certificate | SGS |

Wecare Industrial Company is a world leader in the custom design and manufacture of metal component parts.

We are a full-service company. Our experienced engineers and manufacturing staff are ready to assist you with the design of your custom industrial components and produce the finished part. Our manufacturing capabilities include machined parts, die castings, sand casting and investment castings using the most advanced equipment.

Our services including the following;

. Engineering design of your custom component part

. AutoCAD and Solidworks 3-D support and service

. Production process support and quality control

Please give Wecare an opportunity to work with you. We pride ourselves on the high quality of our engineering and manufacturing, superior quality control and on-time delivery of your parts. Just as important is that we offer very aggressive prices in an effort to build a strong, long term relationship with our customers. We can provide you with a list of our customers upon request.

Wecare is headquartered in the city of Changzhou, Jiangsu Province, China. We have a satellite office in New Jersey for the benefit of our many USA customers.

What concerns you, What we care and focus.

You Trust, We care

We care quality-consistency and timely delivery;

We care to save your costs, to increase your competitiveness;

We care not only present cooperation, but future and long-term collaboration as well