1. Estimating the part/design structure, checking the best manufacturing process and proper design with lowest manufacturing cost for the parts.

2. Designing the products and mold using Solidworks, UG, PRO/E, AutoCAD, for plastic injection mold design, stamping, deeply drawing mold and die casting mold design.

3. Mold making for plastic injection mold, metal stamping/drawing mold, die casting mould. All mold life is over 1, 000, 000 shoots.

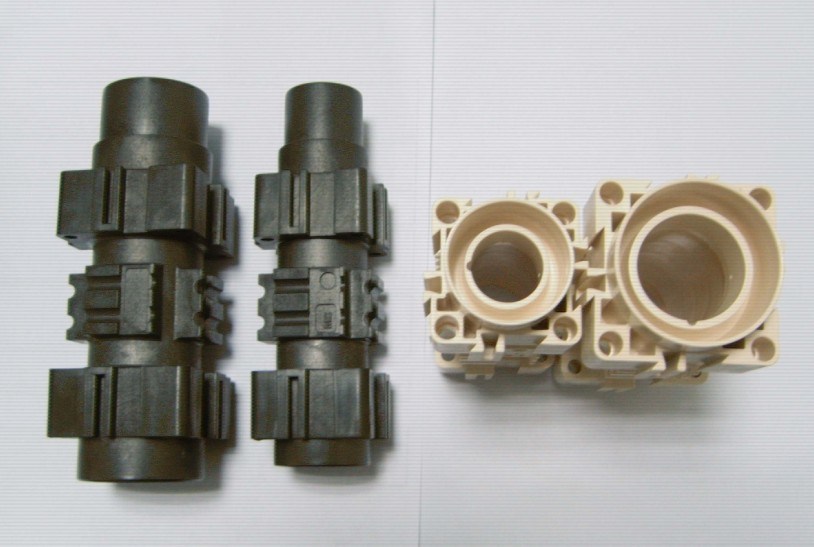

4. Mold trial with different material, Plastic: ABS, PP, PC, PA, SAN, PMMA, PET, PBT, etc.

Metal: Stainless 302/304/210, SPCC, SPCE, Brass, alumina sheet, etc.

5. Molding/stamping mass production for related plastic molding and metal stamping products. 6. Surface treatment such as plastic painting/plating, silk screen. Powder coating and anodizing for metal part surface.

7. Assembly, packing and shipping in a safety way.

MUYOUNG MOULD INDUSTRY LIMITED is a mold maker specialized in builds plastic injection mould, insert mold and Plastic molding in China, with an area of 6000 square meters. Since Muyoung foundation in 2001, has been certified by ISO9001: 2008 and TS169498 quality management systems. At present, we have 105 employees, and the capacity of manufacturing 40 sets of moulds per month. We have 9 years of experience to exported moulds to North America, Europe, Australia, South America, Israel, Middle East and other markets. We always are building top quality moulds with very competitive price and shorter delivery time to help our customers win bigger markets share and profits, and also win us a good reputation.

Muyoung mould is looking to cooperate with our customers in various ways, including close partnerships, international joint marketing cooperation, etc, we hope to become your most valuable partner and invite your inquiries.

We manufacture the mold based on the DME, HASCO, LKM, RABOURDING, FUTABA standard, and we also can design and manufacture molds according to customers' standard or requirements. Steel material: 420/1.2083/H13/1.2344/1.2767/S136/S7/P20/1.2311/4130/NAK80/SKD61/8407

Ability to supply install almost any brand of hot runner system.

Our equipments are working uninterruptedly 24 hours a day

Comprehensive project reporting

Molding parts production

Guaranteed short lead times on the complete project.

We continually persist in the strict and effective quality inspection during processing period, and used advantage measuring equipment for test / inspection

Our high-efficiency team work can provide the customer with shorter delivery time and mould modification completed schedule

Our professional engineers and tool makers have more than 12 years' experience in exported molds

We provides optimize tooling solution and PRO-production design, we will inspect every detail before the mold is exported, and we can provide the mold test video and mold trial report for your reference, if there's any problems during the injection process, we will provide technology support and reasonable solutions, even provide new parts of mold for customer.

Our designers have the training and sophisticated tools required to ensure that parts are designed for efficient production and optimum performance. Let us help you get the right molded plastic part for your next project.