Tin/Ticn Coating Punch/Mold Component Stamping Part (MQ004)

| Price: |

US $ 0.1-0.915/Piece |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

1/Piece |

| Pay Type: |

L/C,T/T,D/P,Paypal,Money Gram |

Specifications1. Manufacturing Enterprise

2. ISO9001-2008 Certified

3. Size can be customized

4. Stable and continuous production abilityProduct detail Our main products: MQ manufactures a full line of standard and customized punch products, carbide punches, punch pins, bushings, ejector pins, step pins and other mould accessories, die parts and machinery parts etc.Designed and manufactured for sound performance and long service life. Our products are manufactured to exacting tolerances to assure interchangeability. Each component is made of quality material. 1. Various material choices: our parts are made with carbide, HSS, ASP Series, SKD11, SUJ2 etc. All our materials are from reliable material suppliers who can grant us material certificate 2. Highly polished surface:our parts are made with precision grinding which ensure polished surface to extent the life span of the partsPlease specify the details making as follows when you inquiry1. The shape of products you need.2. The material you want to use.3. The products' size and requested precision.4. The coating type.5. It would be best to provide your own drawings.

Our main products: MQ manufactures a full line of standard and customized punch products, carbide punches, punch pins, bushings, ejector pins, step pins and other mould accessories, die parts and machinery parts etc.Designed and manufactured for sound performance and long service life. Our products are manufactured to exacting tolerances to assure interchangeability. Each component is made of quality material. 1. Various material choices: our parts are made with carbide, HSS, ASP Series, SKD11, SUJ2 etc. All our materials are from reliable material suppliers who can grant us material certificate 2. Highly polished surface:our parts are made with precision grinding which ensure polished surface to extent the life span of the partsPlease specify the details making as follows when you inquiry1. The shape of products you need.2. The material you want to use.3. The products' size and requested precision.4. The coating type.5. It would be best to provide your own drawings.

|

Product name |

Precision threaded Brass insert |

|

Materials Available |

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420 |

|

2. Steel:C45(K1045), C46(K1046),C20 |

|

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40) |

|

4. Bronze: C51000, C52100, C54400, etc |

|

5. Iron: 1213, 12L14,1215 |

|

6. Aluminum: Al6061, Al6063 |

|

7.OEM according to your request |

|

Products Available |

CNC Machining, Mould Components, Die Components, CNC Turning Parts, Precision Machinery Parts, Plastic Injection Molded Parts, Die&Mold Accessories, Stamping Parts, Centerless Grinding Parts, Metal Hardware Parts, etc. |

|

Surface Finish |

annealing, natural anodization, heat treatment, polishing, nickel plating, chrome plating, yellow passivation, gold passivation, galvanizing, satin, etc. |

|

Processing Method |

cnc machining, turning, milling, drilling, grinding, broaching, welding and assembly |

|

QC (inspection everywhere ): |

Technicians self-check in production |

|

Size |

customized |

|

Tolerance |

± 0.01mm |

|

offset distance |

± 0.02mm |

|

Package |

As per customized specifications |

|

Certificate |

ISO9001:2008 |

|

Description |

High-quality, rich manufacturing experience |

|

Lead Time |

5-7days samples. 7-10days off i cial order |

| Prod Model: |

MQ004 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

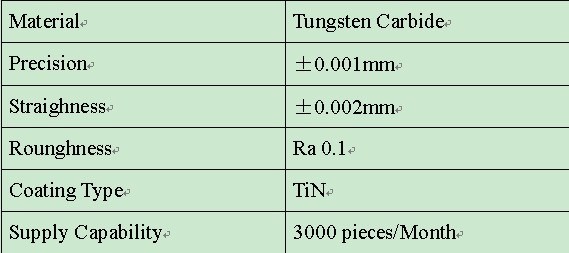

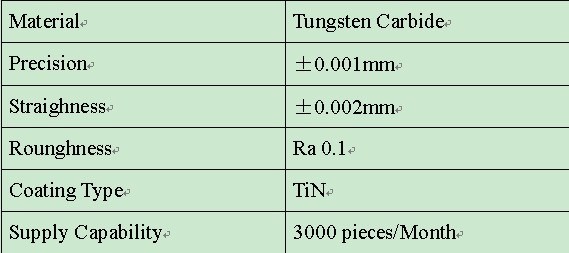

| Material: |

CD650 |

| Price: |

Manufactury Price |

| Delivery Time: |

Generally 7 Workdays or According to Quantity |

| Finshed: |

Titanizing |

| Quality Control: |

100% Inspection on Critical Dimensions |

| Productin Range: |

Part ID From 2-500mm with Tolerance +/-0.01mm |

| Experience: |

10 Years of Professional OEM Service |

| Ability: |

to Develop Hundreds of New Parts Annually. |

| Supply Chain Process: |

Ppap |

| Tolerance: |

+/-0.01mm or +/- 0.0004" |

| Shaping Mode: |

Blowing Mould |

| Application: |

Hardware |

| Installation: |

Fixed |

| Process Combination Type: |

Compound Die |

MQ Precision Hardware Co., Ltd, is located in Dongguan City, Guangdong Province, China. Development of the times, industrial upgrading, MQ accumulated years of

Experience. Professional technology, spirit of innovation, humane management and human philosophy quality are the cultural spirit of MQ entire enterprise. Cultural influence by the work team to make full use of advanced technology, the idea for the technical design will be more delicate and professional, more sophisticated manufactured the perfect product; And dedication to provide quality integration technology service to customer.

MQ used raw materials come from: ASSAB STEELS Co., Ltd and Hitachi Metals Co., Ltd and Kennametal. Ensure the raw materials stability, never use inferior raw materials is our purpose!

MQ committed to professional: Tools parts of automation, machinery parts machining, professional tungsten forming grinding, Ceramic parts processing, Variety of precision metal and plastic mold development and manufacturing, Standard and non-standard parts customization. Can be provides technical support and sales Japanese MISUM / 0 standard, the U. S. DME / 0 standard, German HASCO / 0 standard and other European or the international brand standard mold parts ( excluding patent product ) of Chinese manufacturing, its products are widely used: Metal machinery, automobiles, motorcycles, electronics, electrical appliances, medical equipment, space industry, LED lighting etc different areas.

MQ has passed ISO9001: 2008 international quality management system certification and related third certification report, and import the advanced ERP management system that allows the company's production processes and management systems to rationalize; Scientific.

Quality Policy: Quality win market, Integrity casting brand, Never use inferior raw materials

Business philosophy: Continuously innovative technology, Provide High-quality products, Meet customer requirements, management based on man, cooperation creates value.

Honest and trustworthy, win-win cooperation, sustainable development.

Our commitment:

The most stable quality The most competitive price

The speed of delivery is instantaneous 24 hour rapid response

Excellent team spirit Professional technical support

Reduce the consumption of resources Provide environment-protection products

Adheres to the quality as the center, sustainable development, sustainable management, professional serious attitude, committed to serve you.