Features:

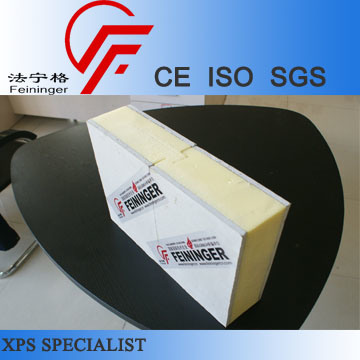

Brand Name: Feininger

Density of XPS: 28-55Kg/m³

Heat Conductivity: 0.02-0.03

Compressive Strength: 150-1000Kpa

Raw Material: XPS board, calcium sulfate board

Color of XPS: Blue, yellow, pink, etc.,

Working Temperature: -50--+75 Celsius

Main Function: Thermal insulation, waterproof

Coating Board: Calcium sulfate board

Inner Board: XPS board

Water Absorption: ≤ 1.5%

Specifications:

1. Heat preservation and insulation

2. Excellent fireproof and waterproof performance

3. Good alkali / acid resistance

4. Good weather resistance (anti-thawing, anti-freezing)

5. Light weight

6. Stable dimension, low expansion rate, low contractibility, low thermal conductivity

7. Eco-friendly, energy conservation

8. Easy to cut & install

9. Labor saving

Main Characteristics:

1. Fire-resistance Grade: B1 Grade, B2 Grade

2. Energy Saving: Adjust the indoor temperature at a constant range to save the electric.

3. Environment protection: Feininger XPS sandwich board will not volatilize hazardous substances and decompose or mildew in the use. It has good corrosion resistance.

4. Easy to Install: Feininger XPS sandwich board is easy to be installed. Not easily affected by the weather, the installation of Feininger XPS sandwich board is three times faster than ordinary materials.

5. Cost Saving: Feininger XPS sandwich, short construction period, can save the labor cost, transportation cost, installation cost and maintenance, etc., can significantly reduce operating expenses in future.

Product Description

Composition: Calcium Silicate Board (face panel) + XPS (core) + Calcium Silicate Board (face panel)

Size(L*W*T): 1180-3000mm * 600-1220mm* (60, 90,120,150,180mm)

Usage: Interior and exterior partition on steel or concrete structure building ,for new construction, additions or renovations.

Advantages: Light weight, sound insulation,heat insulation and preservation, water proof, fire proof, fast construction, save space and so on...

Description:

XPS Sandwich Panel is a kind of light weight energy saving wall material taking calcium sulfate board as face panel, xps (extruded polystyrene) as core and forming by one time compound. It can widely be applied to wall materials of various high and low buildings such as: bank, office building, hospital, school, hotel, shopping mall, amusement hall, old house reconstruction, residence and workshop.

The panel specification could be custom made as per different requirement. They could be transported, installed or uninstalled fast and easily. T panel, wall panel and L panel could be applied freely to reach a scientific design, simple and practical as well as cost saving purpose.

Features:

1. Heat preservation and insulation

2. Excellent fireproof and waterproof performance

3. Good alkali / acid resistance

4. Good weather resistance (anti-thawing, anti-freezing)

5. Light weight

6. Stable dimension, low expansion rate, low contractibility, low thermal conductivity

7. Eco-friendly, energy conservation

8. Easy to cut & install

9. Labor saving

Main Characteristics:

1. Fire-resistance Grade: B1 Grade, B2 Grade

2. Energy Saving: Adjust the indoor temperature at a constant range to save the electric.

3. Environment protection: Feininger XPS sandwich board will not volatilize hazardous substances and decompose or mildew in the use. It has good corrosion resistance.

4. Easy to Install: Feininger XPS sandwich board is easy to be installed. Not easily affected by the weather, the installation of Feininger XPS sandwich board is three times faster than ordinary materials.

5. Cost Saving: Feininger XPS sandwich, short construction period, can save the labor cost, transportation cost, installation cost and maintenance, etc., can significantly reduce operating expenses in future.

Packing Way of XPS fire rated insulation board:

Plastic Bag Packing

68.4M3/40HQ

Container Loading

Feininger has been engaged in foam extrusion technology and its industrialization since 2003. We are located in Nanjing City, Jiangsu Province and it takes 2 hours to Shanghai. Nowadays, Feininger becomes the leading supplier of both XPS extrusion line and XPS foam in China.

Success in plastic foam extrusion requires experiences and innovation. We integrate polymer foaming techniques and machine building skills into our production of XPS Extrusion Machine. We are able to offer completely turn-key project consulting services for foam extrusion plants.

Bearing certifictes of CE, ISO9001, ISO14001, Feininger ensures excellent management of machine manufacturing as well as xps foam production.

May we walk hand-in-hand in the filed of XPS foaming industry!