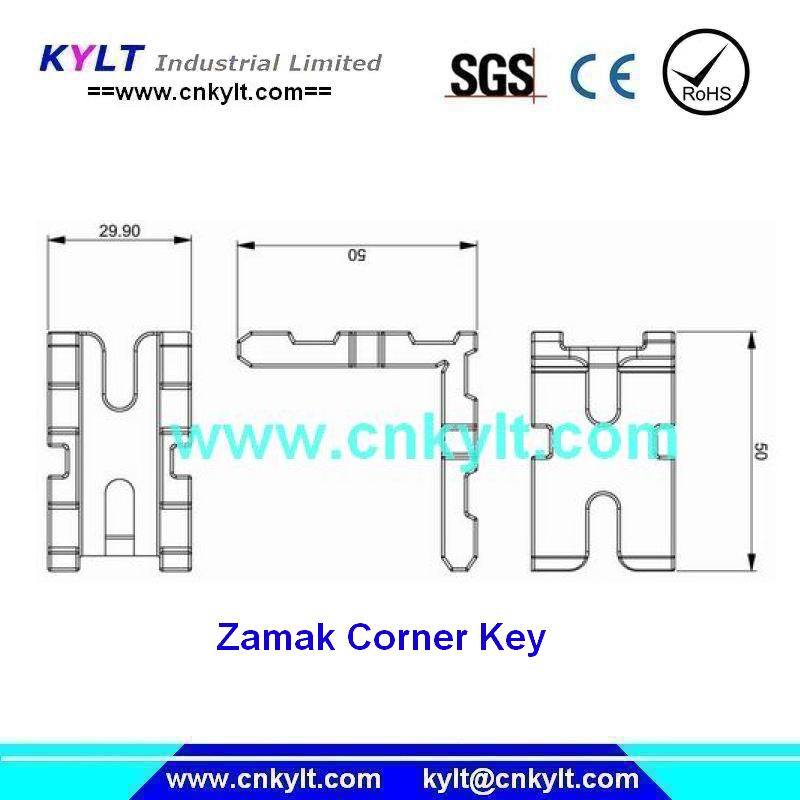

Home Mould Products Zinc Corner Key Pressure Moulding Parts for Construction Decoration Assembly

Zinc Corner Key Pressure Moulding Parts for Construction Decoration Assembly

| Price: |

US $ 0.1-3/Piece |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

100/Piece |

| Pay Type: |

L/C,T/T,Western Union |

Customerized Zinc / Zamak Metal Alloy Die Casting Corner Keys & connectors Used to connect Construction Decoration materails

.

This kind of Corner Keys cast by Zinc(zamak) alloy, that parts are used in construction and decoration.

Material: Zinc die cast

Surface: Raw material

The parts are not visible in building and decoration.

Customerized Aluminum/Zinc/Zamak alloy metal die casting parts

Products Of Aluminum Zinc Alloy Description:

KYLT Industry Co., Ltd. is a professional die casting manufacturer in China.

KYLT focus on samll-middle enterprises, provide die casting solutions as per clients demands from Moulds making, Aluminum / Zinc (Zamak) / Lead (PB) Metal Alloy Die Casting to Machining, Surface treatment, Assembly and Shipment etc.

Our Aluminum Zinc Die Casting Parts are vary from home appliances, office appliances, precise automotive industries to spare parts of industry hardware and etc

With good quality, KYLT die casting parts are export to Japan, Spain, English, Germany, USA etc.

Equipments List:

*Hot chamber die casting machine3: 3sets (Tonnage: 30T~100T)

*Cold chamber die casting machines:4sets(Tonnage:180T~500T)

*CNC:4sets

*Others: Drilling machines, Polishing machines, Milling machine

Aluminum Die Casting Materials:

-ADC12, A380 etc

Zinc (Zamak) Die Casting Materials:

-Zamak2, Zamak3, Zamak5, Zamak7, ZA8, ZA27 etc.

Moulds Making:

-Moulds design, making, maintain in house

-(OEM) Customer provides UG, Solidworks, CAD drawings etc

-(ODM) Customer show us detail ideas and requirements, our engineers will to design.

-Molds productions period is about 3 to 4 weeks.

-Provide die casting samples for customer to check.

Die Casting:

--7sets die casting machines, 2 or 3 shifts to guarantee production in time.

--Experienced die casting and mould makers, 7*24 await orders to guarantee moulds and machines running good.

--Only use standard enviroment friendly Aluminum, Zamak alloy materials. Provide MATERIAL CERTIFICATE from original material factory.

--Provide CE, ROHS, SGS certificate as per customer requirements.

Machining:

--Finish lathing, drilling, tapping, milling, CNC machining works in house

Surface Treatment:

--As per customer requirements, KYLT provide die casting parts surface treatments methods: deburring, shot blasting, shacking polishing by machine (smooth polish or light polish), manual normal polishing, manual bright polishing, painting, powder coasting, galvanization,chrome plating etc.

Packing and shipment:

--FOB, CFR, CIF, EXWORKS trade term available.

--Packing by cartons and in pallets.

--Die casting samples can be send by DHL, FEDEX, UPS, TNT, EMS etc

For more informations and quotations of Aluminum / Zinc / Lead metal alloy die casting parts, please feel free to contact with us:

Contact Stone

www.cnkylt.com

Mob: 0086-15195010186

| Prod Model: |

Zn Zamak Alloy |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Machining Methods: |

Drilling, Lathing etc |

| Aluminum Alloys: |

ADC12, A380 |

| Zinc(Zamak) Alloys: |

Zamak2, Zamak3, Zamak5, Zamak7, Za8, Za27 |

| Surface Treatments: |

Bright Polish, Painting, Powder Coating, Plating |

| Material: |

Zinc Alloy |

| Surface Preparation: |

Polishing |

| Application: |

Gas Regulator, Auto Parts etc |

| Machining: |

Drilling, Tapping |

KYLT Industrial Limited Company focus on providing Die Casting Solutions of Aluminum, Zinc(Zamak), Lead(PB), Copper(Brass), Magnesium metal alloy for Middle-Small enterprises.

As experienced die casting solutions supplier and manufacturer, KYLT provide products and services involve: Cold /Hot Chamber Die Casting Machines (zinc alloy injection machines & lead alloy injection machines), Molds making, precision Aluminum / Zamak metal alloy die casting, Plastic injection, Surface treatment, Assembly etc.

1. PLC Horizontal Cold Chamber Die Casting Machines:

--Tonnage: 150T, 160T, 180T, 220T, 280T, 300T, 350T, 400T, 550T, 700T, 850T, 1100T, 1300T, 1600T, 2000T

--Useage: Aluminum, Copper/brass, Magnesium, Zinc(Zamak), Lead(PB. ) alloy die casting parts of Automotive, Motorcycle, Lamps and lanterns, Pneumatic components, diesel engine, Furniture, Telecommunication etc military industrial and domestic lines.

--Operation method: By PLC. Manual, Semi-Automatic, Full-automatic with ancillary equipments(Automatic Ladling, Spraying Machine, Extractor etc)

--Service: Provide die casting plant diagram, and technical support before and after sales services.

Full automatic PLC Hot Chamber Die Casting Machines:

--Tonnage: 12T, 12T plus, 15T, 18T, 20T, 22T(Horizontal, Vertical types)

--Useage: Zinc(Zamak), Lead(PB. ) alloy parts of Automotive, Motorcycle, Hand t& pneumatic tool, Metal Zippers, Lead Acid Battery Bushings and Terminals, Metal Jewelry / Button / Arts & crafts, Brake cable zamak ends, Battery bolt terminals, PB alloy fishing sinkers etc.

--Operation method: By PLC. Manual, Semi-Automatic, Full-automatic

--Service: Making molds as per clients drawings, Machine test with customer moulds is allowed. KYLT will send test samples to end user by TNT, DHL, UPS ect. And provide testing videos and photos. After sale, any operation questions will be replied with 24hours.

Die Casting and Injection Parts:

--Cold and Hot Chamber Die Casting Machines: 30T - 500T

--Plastic Injection Molding: Horizontal and Vertical injection machines

--Materials: Aluminum, Zinc/Zamak; ABS, PP etc plastics

--Machining: CNC, Drilling, Lathing, Tapping, Milling etc

--All die casting and injection moulds are finished in house, maintain and repair easily to guarantee production in time.

4. Surface treatment:

--Shacking Polish, Shot blasting, Manual polishing(Normal & Bright surface), Painting, Powder Coating, Plating, Pad printing, Silk printing etc.

5. Assembly:

--As per customers demand, KYLT can ready die casting parts, plastic injection molding parts, stamping punch parts, welding parts, electric elements etc by ourselves, and assembling them in house. Provide A Finished Project for clients.

6. Packing:

--As per clients requirements

--Good quality Cartons and Pallets

7. Transportation:

--FOB, CFR, CIF, EXWORKS trade methods are allowed

--Samples and spare parts can be send by UPS, TNT, FedEx, EMS, DHL etc.

--Factory near Shanghai and Ningbo Ports, Air and Sea shipments are conveniently.

KYLT as "ONE-STOP" service supplier, with good quality & excellent service, ourcold / hot chamber die casting machines and precision metal alloy partsare export to Brazil, India, Peru, Ecuador, Yemen, Spain, Germany, UK, USA etc countries and regions.

KYLT looking forward to cooperate with you!

Sincerely Yours!

Stone

Www.Cnkylt.Com

Mob: 0086-15195010186