| Prod Model: |

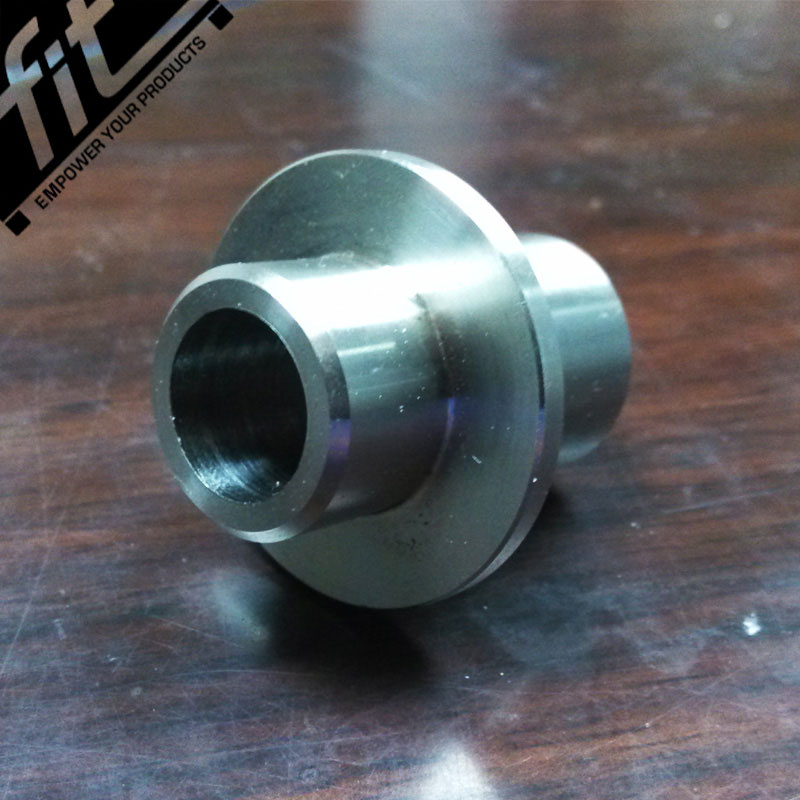

OEM custom cnc part/machining part |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Type: |

CNC |

| Material: |

Aluminuml |

| OEM Custom CNC Part/Machining Part: |

OEM Custom CNC Part/Machining Part |

| Process: |

Broching, Drilling, Chemical, Milling |

| Surface Finishing: |

Anodizing, Polishing, Zinc Plating |

| Part Name: |

OEM Custom CNC Part/Machining Part |

Product Description

OEM custom cnc part/machining part

Details:

OEM custom cnc part/machining part

Materials: stainless steel, nickel alloy, steel and brass

Surface treatment: plating, powder coating, phosphate and anodizing

Processing method: casting, forging, extrusion, CNC milling, turning, grinding, honing, lapping, broaching and other secondary machining

Inspection machines: CMM, projector, universal testing machine, surface gauge and screw gauge

OEM services are welcome

| Name | OEM custom cnc part/machining part |

| Material: | Stainless steel, brass, copper, A356, Al6061,A357 and variety |

| R&D capacity: | 1) Mould/Tooling analysis, design & manufacturing

2) Mould/Tooling testing & confirm the sample

3) CNC machining

4) Surface treatment: Trimming, polishing, cleaning & power coating

5) Full Inspection

6) Packing |

| Production Equipments: | Photo show as below |

| Machining Equipments: | 1) CNC milling and turning, grinding, honing, lapping, broaching and other secondary machining.

2) integral CNC machineries & four machining centers, such as milling, broaching, drilling, turning, planning, grinding machinery and three-axle machining centers.

3) CNC Milling Machine

4) CNC Lathe Machine

5) 4-axis machine |

| Test Equipments: | 1) Hardness tester

2) Chemical analysis

3) Digital Measuring Projector

4) Dynamic Balancing Tester

5) Universal testing machine & Coordinate-Detector for CNC machining

All test machining can ensure high precision CNC machining parts |

| Quality Certification: | 1) ISO 9001-2000

2) TS16949 |

| Surface Treatment: | 1) Sand blasting

2) Zinc/chrome plating

3) Powder coating

4) Anodizing,

5) Heat treatment etc for CNC machining

6) Other customer requirement |

| Production usage: | 1) car parts

2) motorcycle parts

3) pump parts

4) locomotive parts

5) machinery parts

6) metal parts

7) CNC machining

8) machined parts

9) precision machining, etc.

|

Fit Precision Mold(FPM) was formed on the principals of providing the highest quality plastic injection mold, die casting mold stamping mold and pressure mold. FPM is a professional manufacturer of alls size of plastic and die castin & metal parts for all types of industries.

We take pride in the best technical support to our customers with our world-class engineering team.

We are a one stop shop to all your mechanical design and manufacturing needs. Our primary customers are: Research and development institutions Electrical and mechanical product design companies Injection molding companies Mechanical design consulting Companies Original equipment manufacturers(OEM).

Fit Precision Mold(FPM) was formed on the principals of providing the highest quality plastic injection mold, die casting mold stamping mold and pressure mold. FPM is a professional manufacturer of alls size of plastic and die castin & metal parts for all types of industries.

We take pride in the best technical support to our customers with our world-class engineering team.

We are a one stop shop to all your mechanical design and manufacturing needs. Our primary customers are: Research and development institutions Electrical and mechanical product design companies Injection molding companies Mechanical design consulting Companies Original equipment manufacturers(OEM).