| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Shaping Mode: |

Injection Mould |

| Installation: |

Fixed |

| Process Combination Type: |

Compound Die |

| Application: |

Cutlery Mould,Tableware Mould |

Product Description

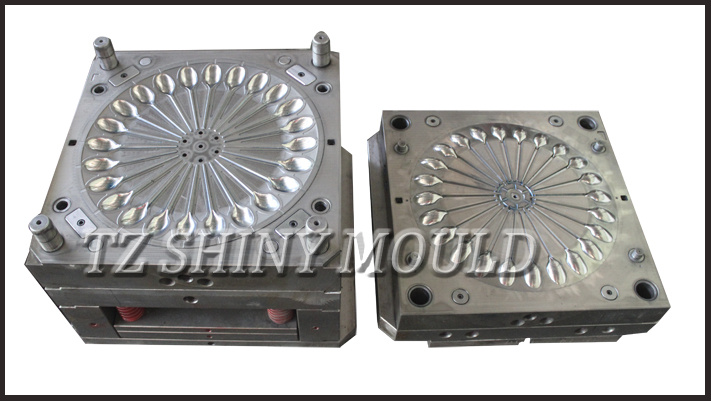

PS Spoon injection mould

TZSHINY MOULD has extensive experience in making thin wall plastic cutlery mould with multi cavities,

High quality moulds attract many customers from all over the world.

1)Product: 2.5Gram PS fork

Mould size: 545*545*430mm

Suitable injection Machine: 250Tons

Cavities No.: 24

Mould weight: 1018kg

Mould steel: H13 vacuum quench, HRC48-52

Mould life: 3 million shots

Injection gate: 1 tip hot runner

Production Efficiency: 7200PCS as per hour (Cycle time: 12s)

TZSHINY MOULD also have built many other multi cavity cutlery moulds, welcome to visit our factory to negotiate more details.

|

Pre-production proposal |

We offer professional & practical solution for your investment |

|

Mould process report |

Weekly report, mould trial video and samples for your checking |

|

Mould design approval |

2D/3D mould drawing & mould manufacturing schedule for customer’s approval |

|

Quality Written warranty |

Steel cetificate, mould trial report, parts measuring report, operating instructions, maintenance specifications |

|

Spare parts |

wearing spare parts provided |

|

After service support |

Provided |

|

Communications |

Email, phone, Trade Manager, Msn, Skype, yahoo |

|

Advantage |

Skilled Language to ensure good communion |

|

Special in exported mould,experienced in international standard |

|

Rational mould design to extend mould life,and to get high production efficiency, |

|

Precision Machining to fine parting line effect |

Taizhou Shiny Mould focus on innovation of mould design for plastic injection mould and blow moulds. As a mould manufacturer, we have yearly production ability of 200 sets 4.0 tons moulds, the maximum moulds that we can make is L2.0 mx H1 m /15 tons in weight. Until recently, we have sold many moulds to Brazil, Russia, Ukraine, Spain, Poland, mainly South America and Europe customers.

Our mould making experience mainly acquired in:

-Packaging bucket Mould

-Thin wall mould

-Cap mould & Preform mould

-Crate mould & Pallet mould

-Household plasticware mould

-Plastic Component mould

Mould Design Ability:

1. Product design by 3D software according to concept or samples;

2. Mould design by 3D and 2d software according to requirements;

3. Software: Auto CAD, Unigraphics, PRO/engineer; Cimatron;

We provide services includes:

1)pre-production proposal to help customers to have steady production;

2)in-production shcedule weekly report by photos and video;

3) after-sale online support and spare parts supply support;

Our Advantage:

Good Excution of innovation to mould design,

Concentration on every order to ensure in-time delivery,

Matchable competitive mould price,

With the tenet "Service, Price, Trueheartedness", Shiny Mould is developing steadily and will have a more bright future with your regular orders! All your enquiries with specification will be answered within 2 working days. We are ready to learn from you and excute your mould designs. Welcome to visit our factory when you are in China to learn more about TZShiny Mould!

Taizhou Shiny Mould focus on innovation of mould design for plastic injection mould and blow moulds. As a mould manufacturer, we have yearly production ability of 200 sets 4.0 tons moulds, the maximum moulds that we can make is L2.0 mx H1 m /15 tons in weight. Until recently, we have sold many moulds to Brazil, Russia, Ukraine, Spain, Poland, mainly South America and Europe customers.

Our mould making experience mainly acquired in:

-Packaging bucket Mould

-Thin wall mould

-Cap mould & Preform mould

-Crate mould & Pallet mould

-Household plasticware mould

-Plastic Component mould

Mould Design Ability:

1. Product design by 3D software according to concept or samples;

2. Mould design by 3D and 2d software according to requirements;

3. Software: Auto CAD, Unigraphics, PRO/engineer; Cimatron;

We provide services includes:

1)pre-production proposal to help customers to have steady production;

2)in-production shcedule weekly report by photos and video;

3) after-sale online support and spare parts supply support;

Our Advantage:

Good Excution of innovation to mould design,

Concentration on every order to ensure in-time delivery,

Matchable competitive mould price,

With the tenet "Service, Price, Trueheartedness", Shiny Mould is developing steadily and will have a more bright future with your regular orders! All your enquiries with specification will be answered within 2 working days. We are ready to learn from you and excute your mould designs. Welcome to visit our factory when you are in China to learn more about TZShiny Mould!