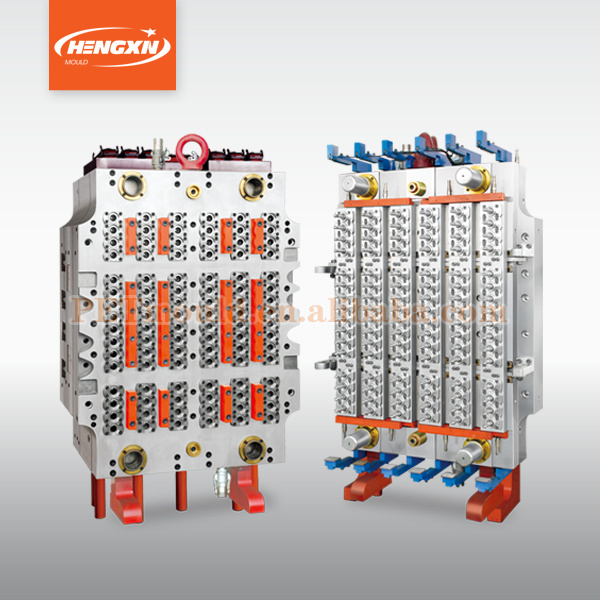

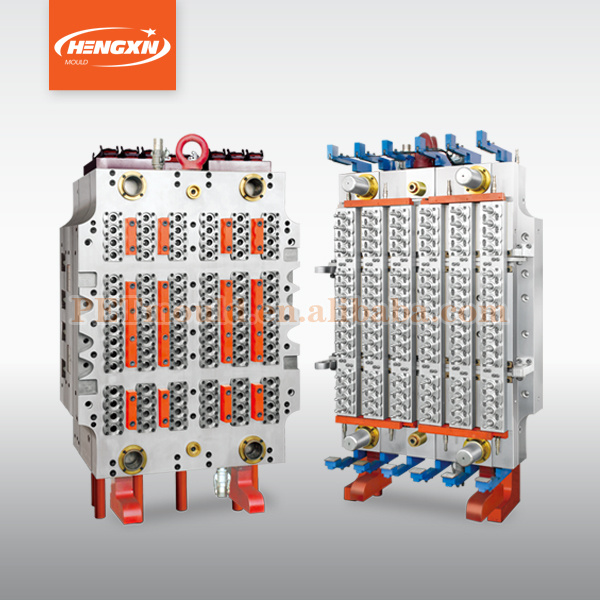

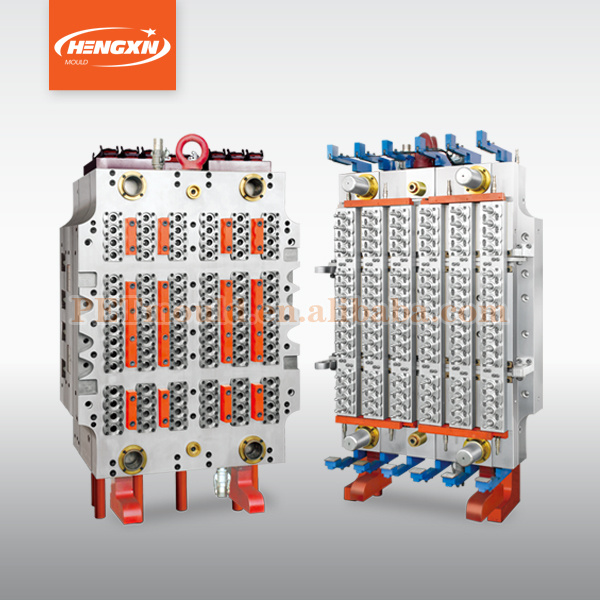

96 Cavities preform mould

Specifications

1. Material: 2316 Steel, P20

2. Cavity: Single/Multi

3. Runner: Hot/Cold

4. Type: Air seal/short tail/long tail

5. One million Grantue

1. The mould is desigened with 3D modeling software

2. The mould is made by imported P20 and German 2306 seteel etc.

3. The mould is designed by advanced hot Runner system and each cavity has independent temperature control and heater system.

4. The mould surface is plated by reliable hard chrome.

5. The mould cavity is replaceable, so that the label top can be changed.

6. All the parts are manufactured with CNC equipments.

PET Preform Mould Main Components Specification and Advantages

Main component

Specification and Advantages

Core

2316 steel from Sweden

High-quality special mould steel from Sweden (HRC >45) gurantee 2 million shots without any maintenance

Neck

S136 steel from Sweden, HRC >60,

International standard screw neck

Cavity

2316 steel from Sweden

Each cavity have an independent temperature controller

Each cavity self-clamp independently, ensure mould concentricity. 0.05-0.06mm

Body

P20 Steel material from Germany

Hotrunner plate

2344 Steel material from Germany

Slider Plate

Wear-resistant copper

Specially designed cooling circuits

Proper design reduce molding cycle time to 15 seconds( with proper water chiller and injection machine) about 3-5 shots per minute

Hot runner design

Make sure the high quality of preform products.

Heater

Anole Germany

Valve gated design with Automatic drop

Each cavity has its independent heating zone and temperature is measured by independent thermocouple...(advantages: Easily avoid some problems such as white or drawbench on bottom).

Valve gated type without tail reduces labor force.

Precessed by high presion CNC machine and numerical control loathe machine

Lowest weight and dimensional variation

Thickness between max. Part and min. Part is not more than 0.05mm make sure that every parts can match well

|

PET Preform Mould Main Components Specification and Advantages |

|

Main component |

Specification and Advantages |

|

Core |

2316 steel from Sweden |

high-quality special mould steel from sweden (HRC >45) gurantee 2 million shots without any maintenance

|

|

Neck |

S136 steel from Sweden, HRC >60,

International standard screw neck |

|

Cavity |

2316 steel from Sweden

Each cavity have an independent temperature controller

Each cavity self-clamp independently, ensure mould concentricity. 0.05-0.06mm |

|

Body |

P20 Steel material from Germany |

|

Hotrunner plate |

2344 Steel material from Germany |

|

Slider Plate |

wear-resistant copper |

|

specially designed cooling circuits |

Proper design reduce molding cycle time to 15 seconds( with proper water chiller and injection machine) about 3-5 shots per minute |

|

Hot runner design |

make sure the high quality of preform products. |

|

Heater |

Anole Germany |

|

valve gated design with Automatic drop |

each cavity has its independent heating zone and temperature is measured by independent thermocouple. .(advantages: easily avoid some problems such as white or drawbench on bottom).

Valve gated type without tail reduces labor force. |

|

Precessed by high presion CNC machine and numerical control loathe machine |

Lowest weight and dimensional variation

thickness between max. part and min. part is not more than 0.05mm make sure that every parts can match well

|

Zhejiang Taizhou Huangyan Hengxin Mould & Plastic Co., Ltd (Hengxin) was established in 1992.

Hengxin occupies more than 10, 000 square meters workshop and has more than 100 employees.

Hengxin is specialized in PET perform mould, cap mould, bottle blowing mould, household mould.

With many years rich experience, Hengxin become one of Chinese leading and famous suppliers of PET preform mould. Especially we design and manufacture self-lock PET perform mould and shut-off nozzle PET perform mould by ourselves.

Hengxin moulds have been well received abroad in Italy, Russia, Africa, Southeast Asia and the Middle East as well as at home.

We also set up several agencies for supplying business consultation, technology support and after-sale service at home and abroad.

"To survive by quality, to develop by creditability, to satisfy the customers" are our guidelines.