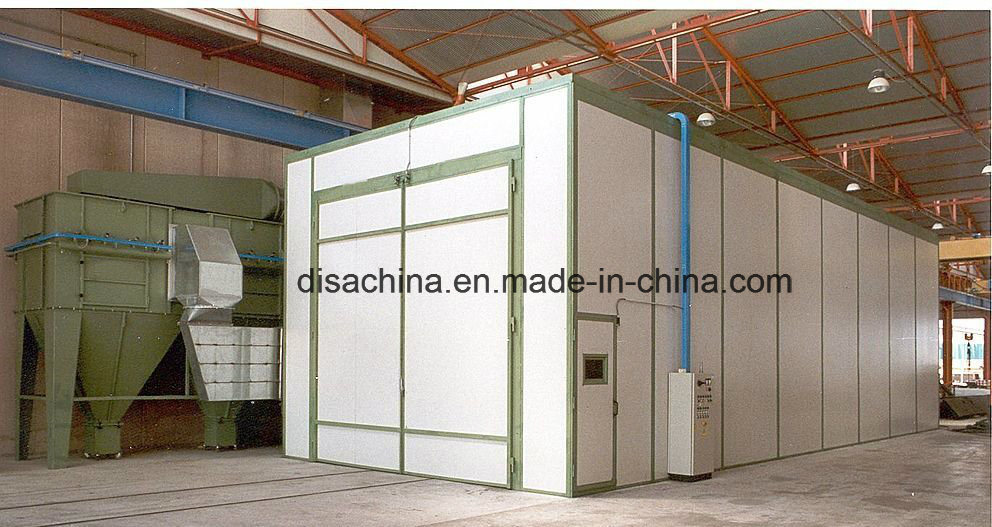

Disa Sand Blasting Machine

| Price: |

US $ 200000/Piece |

| Trade Terms: |

FOB |

| Min Order: |

1/Piece |

| Pay Type: |

T/T |

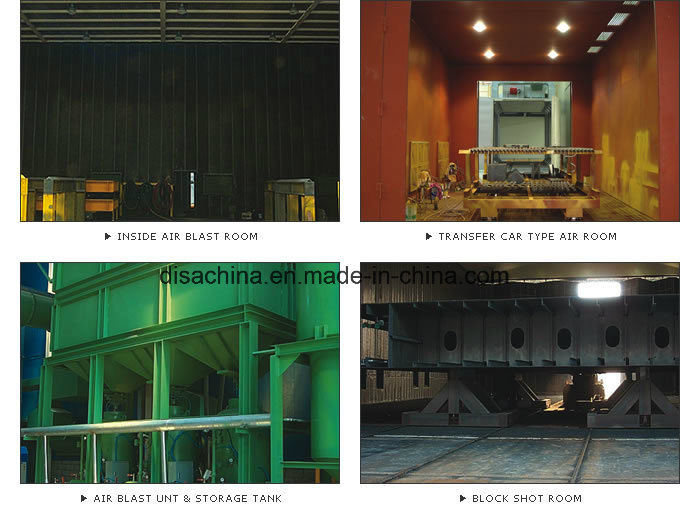

Sand blasting room is mainly used for shipyard cleaning, sub parts and components processing, steel surface treadment,derusting, descaling, welding slag clean-up, strengthening the sub parts, components and steel.Let surface have a certain roughness, increase the echoing force and the strength and corrosion-resistance. Sand blasting room includes: cleaning room body, blasting systems, abrasive circulatory system, ventilation and circulation system, air supply system, flexible door lifting system, electric control system etc.. Paint drying system is mainly composed chamber body, air supply heating systems, air filtration system, air filtration system, paint mist filtration system, lighting system, electrical control system etc.. Sand blasting room has the following advantages:1.Adopts three electric spraying guns.It not only increases the efficiency and sand blasting pressure, but also saving energy. 2.Using a high degree of automation of the blasting system. 3.Completely solve the environment pollution problem generated dust from blasting operations 4.The abrasive can be automatically recovered, sorted and stored. Thereby it can reduce the labor intensity and improve the utilization of the abrasive.5.The production and work can not be limited by space compact. 6.It can supply the operator with sanitary conditions and safety norms of the working conditions. 7.It can maintain a certain temperature and humidity of the construction environment for the painting work.DISA is the largest manufacturer and global distributer of shot blasting equipment and sand blasting room with extensive experience in the industry with various projects and partners. We are proud to provide the highest quality sand blasting room with the best technology and engineers as well as the highest quality service to our customers. Our production of numerous sand blasting equipment types accommodates the needs of each purpose of utilizing these shot blast machines, such as for castings, pipes, pumps, steel surfaces, etc. Sand blasting room is mainly used in the large iron surface cleaning, rust removing and large stainless steel sand blasting. Iron must have sandblasting surface treatment in order to obtain rough flat surface for improving the coating adhesion before the coating. The stainless steel surface is cleaned and can meet the requirement of inferior smooth by our shot blasting room. (If users are not familiar with stainless steel sand blasting process, our factory can provide mature process.)

When the sand blasting room is working, peening grits will be transported to the lifting device by a screw conveyor from the discharge chamber. Then go back into the sand box. And recycle to sandblasting pipe for circulation use.

Sand blasting room dust removal system has composed of the separator, dust collector, fan, water spray type of export, water tank and water pump.Features

1. Performance of descaling and cleaning work requiring accurate and sophisticated process, such as shell molds,

Die-casting patterns Precision castings, Air conditioner, and Components.

2. Produced in an airtight way, it keeps the working environment pleasant because there is no dust scattering from abrasive materials.

3. During work, the work efficiency gets amplified through the rotation of the table of the internal cabinet.

4. By installing transfer car, heavy material (product) can be treated.

5. Shifting installation is easy as it is attached integrally to the dust collector.

6. It is appropriate to huge structures(room).

7. The cost of installation has been cut down by simplifying the shifting equipment or abrasive materials.

8. The work efficiency has got amplified by transferring the structure by installing transfer car.

9. The abrasive materials piled on the goods can be efficiently collected by installing Vacuum Recovery. QDS2610 Sand blasting room Technical DocumentsAccording to the production guiding principle and request that proposed by the consumer, the supplier specially designs and manufactures a non-sign equipment QDS2610 sand blasting room documents:I

.Function Outline

QDS2610 sand blasting room is used for Spray Abrasive cleaning the surface of the workpiece. It can increase varnish film adhesion when the work piece is painted, enhance the surface quality of the entire structure by the way of spray abrasive cleaning to remove the the corrosion, the oxide skin and welding slag on the work piece surface.II

. Sand Blasting Room Main Technical Parameter

1.Greatest Size of Processing Workpiece:flat wagon -type cleaning workpiece size(length×width×height) 12000×2000×2000mm

2.Normal Size of Processing Workpiece:flat wagon -type cleaning workpiece size(length×width×height) 1200×600×400mm

3. Cleaning Effect: Reach GB8923-88 A-B Sa2.5 standard, part A-B Sa2.0, The workpiece surface presents metal primary color.

4.Wheel Abrator: type:Q0250-II

-JK(double gun intermittence type), Spraying quantity:1800-2000kg/h, Work barometric pressure:0.4-0.6Mpa, Biggest gas consumption:(2×6.3=12.6 m³/min)

The capacity of shot blast system that we offered is about 1 cubin meter

This sand blasting room system have two 10 mm nozzles it could operated by one persion or by to persion together.

This system offered two guns and this system is a continuous system.

They connect together but they have self-governed control system .they could operated by one persion or by two persion together,and it's a continuous system,so they can spray abrasive without stop .Using one gun or using two guns every gun can get the same efficiency .

Wheel Abrator: type:Q0250-II

(double gun intermittence type), Spraying quantity:1800-2000kg/h, Work barometric pressure:0.4-0.6Mpa, Biggest gas consumption:(2×6.3=12.6 m³/min)

Using 10 mm nozzles neese power :22KW

Using 2-10 mm nozzles neese power :44KW

DETAIL POWER

1.Elevator: lifting power:20t/h,power:1.5kw

2.Master Longitudinal Spiral Conveyor: delivery value:20t/h, power:0.55kw

3.Master Master vertical Spiral Conveyor: delivery value: 20t/h, power:0.55kw

4.Dust Removal System: total dust removal amount of wind: 40000~

46000 m3/h,

power:

22+22 kw

5.light power :200w*14 =2.8 kw

Total Output: approximately 27.4 kw(ex Compressed air power )

Total Output: approximately 49.5 kw(ex Compressed air power )III

. Equipment Composition and Various Parts Explanation

1.Sand Blasting Room cabinet:

The length of normal Hand-held Spray Abrasive cabin is 4000mm*4000mm*3700mm, and its structural style is as follows:

The sand blasting room case of Hand-held Shoot blast Abrasive cabin is a kind of welding structure by steel plate and steel sections. which has enough intensity and rigidity.

The room body interior guard plate uses rubber shield with good barrier propterty whose service life is longer than 5000 hours.

The room body surface is covered with colorized steel plate.

2. The length of greatest Hand-held Spray Abrasive cabin is 11000mm*4000mm*3700mm, and its structural style is as follows:

The body case of Hand-held Spray Abrasive cabin is a kind of welding structure by steel plate and steel sections. which has enough intensity and rigidity.

The sand blasting room body interior guard plate uses rubber shield with good barrier propterty whose service life is longer than 5000 hours.

The sand blasting room body surface is covered with colorized steel plate.

The room body side is equipped with the dust removal tuyere, through which the dust removal system carries on ventilates and dust removal to Spray Abrasive cabinet. The design of dust removal tuyere is based on the principal of "upward delivers, downward inhale and upward discharge" which can agglomerate the dust air current as far as possible to the lower part and increases operator's visibility. The room body top and the side are equipped with 16high luminance flares to guarantee sufficient brightness in the room. Each side of the room body is equipped with emergency exit.The interior of Spray Abrasive cabinet adopts δ6 wear-resisting rubber plate for protection whose protection performance is good with long service life.

The pill-collection hopper is equipped on the bottom of shot-blast cabinet with perforation laminae cribrosa to filtrate projectile. Then only the qualified projectile falls the hopper to carry on duty-cycle utilization, the bulk material falls on the laminae cribrosa and was cleaned up artificially in certain time. By this way, it can protect the projectile circulatory system effectively and safely. It lays down Cr16 orifice casts material on the perforation lamina cribrosa for protection.

3. Air-operated Door:

There are 2 air-operated doors which are installed on the outside of the front sealed chamber, The gate body is a kind of welding structure of steel plate and square tubes which has the characteristics of light weight, good rigidity and long service life.

4.Shot-blast System:

Spray Abrasive cleaning machine is equipt with one set of double-gun intermittence type wheel abrator. According to the operation requirements, it may work alone or work together. The wheel abrator is manufactured by the American Clemco technology and has the following characteristic:Enhances the corrosion resistance ability of the mechanical product and metal moldingAutomatic On-line Refilling: Be able to realize the function of "automatic refill when the projectile is consumpt to the quota, automatic stop when the projectile is added fully".Using the manual type spray gun, the worker controls the spray nozzle to spurt the pill, which can be used for jet eliminating the surface floating ash by after the cleaning up, the jet.The jet power is formidable and stable. Available for long time high pressure continued operation, thus clean-up evenly and in high grade.In order to make the high effective shot-blast machine get good shot-blastign effect, we provide the high effective spray nozzle especially which has high efficiency, good wear resistance, long service life, it is one of the most advanced product of the world.Unifies the electricity control and the gas control, more rapid and reliable to control,convinent for long distance control.

When starts the normal work, puts on the face mask and protective glove well, grips the spray nozzle with both hands, directs the work piece, holds down the sand blasting button of the sand-blasts handle, then starts sand-blasting, adjust air operated sand valve,keeps to adjust untill to be able to see the fuzzy sand in the air current; Holds down jet button of the sand-blasts handle to start jetting which can clean up the float ash on the work piece. The user may choose spray nozzle with different caliber according to the air flow.The operator should obtain the ideal spraying effect through adjusting different spraying angle.

5.Elevator (hopper):

The bucket elevator is composed by speed reducer (SEW), brake electrical machinery (SEW), up-down drum, the polyester core transmission belt, the hopper, the seal lagging and rises-tight installment and so on.

The feed inlet of bucket elevator connects the spiral conveyor, whose discharge port connects the separator. The high anti-friction materialis equipt on the up and lower parts of the elevator for protection.

The elevator lagging adopts the welding structure of bend formation that equipped with access door,convenient for maintaing and replacing the elevator hopper.It can maintain the lower transmission and deal with projectile jamming on the bottom when opening the gate cover of the lower lagging. When it works, the two-row hopper that fixed on the even leather belt blows up the pill material on the bottom of the elevator, then delivers the pill material to the elevator crown under the actuation of elevator electrical machine, finally depends on the centrifugal gravity way to fall the material.The pill material is put into pill-sand separator.

The driving pulley uses the mouse cage type, enhances frictional force between the transmission belt and the band pulley, avoids the belt slipping phenomenon, reduces the leather belt pretightening up force, reduces the pill attrition phenomenon, lengthens the service life of transmission belt.

The elevator is equipped with a set of to tight-rising installment. When the transmission belt loose or runs slantingly, through adjusting the bolt the both sides of the elevator, can make the leather belt tight, remove leaning breakdown problem of transmission belt.

The lower axis of elevator is loaded with pulse wheel which may examine the running status of elevator. When appears the breakdowns of elevator leather belt slip, loose or jamming,it may feedback the signal to PLC immediately, and carry on alaming or gradually stops so as to guarantee the equipment run safely.

6.Separator:

This machine uses advanced BE full-curtain type separator.T

This separator absorbs the American Pangborn Corporation technology and developed by our company which is the newest style separator of our company at present.

The separator is one of the key component of this equipment,whose separation area designing size directly affects separation effect of the separator.If the separation effect is not good, it can not only affect the cleaning up effect but also can speed up leaf blade the attrition of impeller head, reduces its service life, and increases maintenance cost.

The separator's working principle is: The pill and granulated substance mixture flows from the bucket elevator is delivered by the cotton screw to the uper separation area. The cotton screw separates it evenly in the separation area along the separator,forms a pill sand flow curtain like waterfall. At the same time, the dust-removing air blower separates the projectile,molding sand, metal oxide skin fragment, stave projectile and dust in the flowing curtain through convulsion on separator gusty area and using gravity dry separation way which will flow in the bunker after the second filtration by the bottom strainer and store up for the next circulation.

In the falling process,the mixture of pill and granulated substance is affected by horizontal air curren force, thus forms an oblique curvilinear motion path. Because of the difference of pellet proportion and particle size, its oblique degree is different, thus enables the pill and dregs are separated.The dust is inspired by dust remover for purification processing.The garrulous pill, sand and oxide skin are delivered to waste material storage bucket. The qualified projectile and partial scrap sundry goods are sent to pill-storage bucket after once more sieving for the next circulation.

The best separation effect of separator depends on the adjustment of the flow control board position of dry separation area, the adjustment of adjustment board position on filtering panel,adjusting the reed valve wind amount of air hose to realize. It can get good separation effect if the adjustment is reasonable which can keep the separation efficiency above 99%.

The projectile balance of two dry separation area is guaranteed through the supervision to the level-sensing device in the material bucket of separator and the adjustment of automatic control board of dry separation area flow. The flow control board of the front dry separation area is actuated by air cylinder which can automaticly control the flow capacity.

The cotton spiral conveyor is composed by speed reducer (SEW), the screw shaft, the transportation covers, bearing with seat and so on. This part has realized the seriation in our company, with high versatility and interchangeability, stable and reliable performance. The entire screw shaft adopts whole processing after welding, thus guarantee the both sides of screw shaft keep proper alignment. This part is an important constituent in projectile circulatory system of the equipment, whose spiral leaf blade uses the 16Mn material.Its thicknessis is equal to or more than 8mm.The inner and outer annuluses are stretched by special craft with precise pitch and outer annulus size, which can enhance the screw life and reduce movement noise.

The axis of cotton material screw is equipt with pulse wheel which may examine the active status of cotton material screw. When appears the breakdowns of jamming or doesn't transfer, it may feedback the signal to PLC immediately, and carry on alaming or gradually stopping machine so as to guarantee the equipment run safely.

This separator absorbs the American Pangborn Corporation technology and developed by our company which is the newest style separator of our company at present.

In the falling process, the mixture of pill and granulated substance is affected by horizontal air curren force, thus forms an oblique curvilinear motion path. Because of the difference of pellet proportion and particle size, its oblique degree is different, thus enables the pill and dregs are separated.The dust is inspired by dust remover for purification processing.The garrulous pill, sand and oxide skin are delivered to waste material storage bucket. The qualified projectile and partial scrap sundry goods are sent to pill-storage bucket after once more sieving for the next circulation.7. Spiral Conveyor (2sets):

Spiral conveyor is composed by speed reducer (SEW), the screw shaft, the transportation covers, bearing with seat and so on.

This part has realized the seriation in our company, with high versatility and interchangeability, stable and reliable performance. The entire screw shaft adopts whole processing after welding, thus guarantee the both sides of screw shaft keep proper alignment.

The spiral conveyor is installed under the hopper of room body bottom using for transporting the projectile that collectted by hopper to the elevator. This part is an important constituent in projectile circulatory system of the equipment, whose spiral leaf blade uses the 16Mn material.Its thicknessis is equal to or more than 8mm.The inner and outer annuluses are stretched by special craft with precise pitch and outer annulus size, which can enhance the screw life and reduce movement noise.

The screw axis is equipt with pulse wheel which may examine the running status of screw. When appears the breakdowns of jamming or doesn't transfer, it may feedback the signal to PLC immediately, and carry on alaming or gradually stopping machine so as to guarantee the equipment run safely.

The bottom screw is designed to be easily replaced by whole when designing the entire equipment.

8. Air-operated Pill-suppling System:

The air-operated pill-suppling system is mainly composed by 1 sets of projectile strobes, air cylinder, pill-smoothing tube, air-controlling system and so on.

The air-controlling projectile strobe is a patent product of our company which is developed and manufactured independently. It controls the pill ejection quantity through the controlling of air cylinder switch. The reliability is high, avoids the phenomenons of burning electrical machine, jamming impeller head, unfruitfull pill-blasting and injury affairs that caused by lax closure of ordinary projectile control valve,and achieves the international advanced level.It can get the needed pill quantity through adjusting projectile controller bolt or the valve board.

9. Platform Ladder:

The platform ladder of equipment is designed and made in line with the national standard, on which lays down pattern steel to prevent serviceman from slipping.

There are security guard rails around the top of spray abrasive cleaning machine chamber body.

10. Dust Removal System

Dust Removal System: total dust removal amount of wind: 60000~

65000 m3/h,

power:

59 kw

Normal work piece dust removal amount of wind: 18000~

20000 m3/h,

power:

22 kw. This dust removal system of this equipment adopts two-levels dust removal, which are tornado body dust removers and 1 sets of Hsq36 type filter drum dust remover.

Greatest work piece dust removal amount of wind: 40000~

45000 m3/h,

power:

37 kw .Thisedust removal system of this equipment adopts two-levels dust removal, which are tornado body dust removers and two sets of Hsq42 type filter drum dust remover.

The dust gas comes out of every room will go through the dust pipeline and first reach the whirlwind body, to dust settlement larger particles and small part of projectile fragmentation in the dust gas.The dust gas which has been dedusting by the whirlwind body will go through pipeline and reaches cartridge-type dust collector. The dust gas enter into the mixing chamber from the top of cartridge-type dust collector. After filtered by the cartridge, it enter into the net gas chamber, and then discharged from below of cartridge-type dust collector. The gas after second removes dust reaches the chimney through the air blower, discharge in the final high altitude. Efficiency is more than 99.9% to remove dust, the waste gas discharges ≤ 50mg/m3, dust density of on-the-spot post <10mg/m3, the discharge of dust totally accords with the regulation in national standard GB16297-96 " comprehensive discharge standard of air pollutant ".

For the sound, and your neighbors are not far away,also the work should be dong in evening/night too.So we must do enough for shut down the noise.

1. we use special fan that means low-noise fan.

2. The fans have special shield room to obstruct noise.

3. At the top fo fan installed denoise to shut-down noise.

4. Low vent .And at the top of the vent installed air cylinder cover.The vent would be covered when the machine stoped to resist acide air from seaside.

11.The electrical control system:

The electrical control system composed of low-voltage power distribution equipment, electrical components choses products of Siemens or Schneider.

The electrical control system of this equipment uses automatically, manually controlled two ways. Under normal operation using PLC automatic control, and equipment components runes at a pre-order operation procedures; installed and tested, a single or several functional components operation, maintenance commissioning components used in manual control, in order to adjust the equipment easy and facilitate maintenance, and testing the performance of the relevant components.

Users will be responsible for powering Electrical cabinet.

The electrical control system equipment has the following characteristics:All parts of the operation have fault alarm function. If the device is functioning as a component failure, acousto-optic alarm will start immediately, in accordance with the sequence to phase out the operation parts, projectiles blocked completely avoid phenomenon of causing motor burn.Electrical control cabinet size, color, location is determined by the buyer. IV

The main component configuration:

1.the electrical, all reducer with Tianjin SEW products.

2.fans are domestic famous and good quality products.

3.The lighting is Philippe products.

4.PLC is Japan's Mitsubishi products, electrical components using Siemens or Schneider products .

Other information,please check our web:http://www.disamachinery.com/

Other information,please check our web:http://www.disamachinery.com/

| Prod Model: |

QDS2610 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Size As Per Customer's Request: |

Color Can Be Green or Blue or White |

| Clean Type: |

Sand Blasting |

| Certification: |

ISO9001 |

Disa as shot blasting machine international leading supplier in China, has been established for 20 years, Disa known production shot blasting machine, since it sold in 1992 in China, the first such shot blasting machine, in just 20 years has developed rapidly, as of 2011 years on sale to the world more than 200 articles, good to use.

Disa offers you system solutions from a single source - beginning with a project idea to consulting, profitability analysis and individual engineering to a turnkey plant. With 17 years of collective experience, we have rebuilt over 1500 kinds of shot blasting machines. Through the years we expanded our engineering and manufacturing capabilities so that today we are able to take on design problems involving castings, forgings, stampings, steel mill products, fabricating, etc.

Our company supplies different kinds of products. High quality and favorable price. We're pleased to get your Inquiry and we will come back to as soon as possible. We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective.