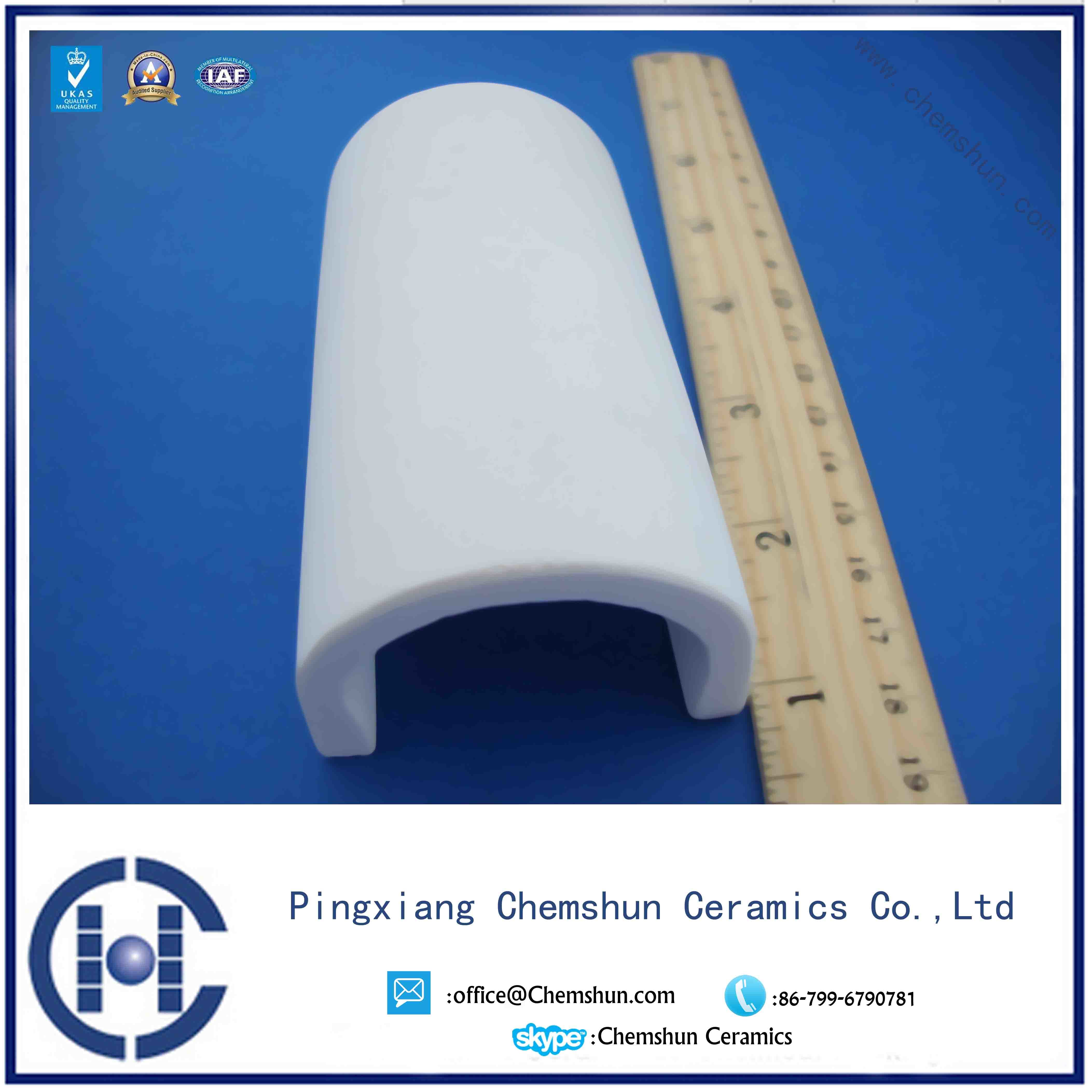

high temperature sintered alumina half-pipe

We pingxiang chemshun ceramics Co., Ltd are a professional manufacturer and exporter of

wear resistance ceramic product. Our product including the alumina tiles(alumina plain tile,

alumina weldable tile, alumina trapezoidal tile, alumina curved tile), alumina mosaic piece

(alumina mosaic square tiles, alumina mosaic hexgonal tile, alumina rectangle mosaic tile,

alumina dimple tiles), alumina cylinders(alumina column) and alumina pipes(alumina tubes,

alumina sleeve, alumina rods, alumina sleeve bush, ceramic lined pipe, T type tube, straight tube,

Y shaped tubes). The mentioned product output is over than 25000ton/year.

We have advanced facility and strictly quality contral system.

The product sells popular in the world market.

Description of high temperature sintered alumina half-pipe:

Wear-resisting alumina pipe in the isopressing technology, the product of high density, the fine grinding surface polishing, and other composite pipe assembly,

is a kind of ideal resistant to wear and corrosion protection material conveying.

Alumina ceramic pipe Can be widely used in mining, metallurgy, chemical, electric power industries of coal powder, ash, liquid aluminum etc material conveying protection process.

It also solve the problem of partially fell off which usually happened to wear-resistant plate or panel.

Alumina ceramic pipe mainly used in papermaking industry, mining separator, cyclones and nozzles as well as textile ceramic components.

Alumina ceramic pipe has promising application in ceramic valves, structure ceramic components and bulletproof ceramic in military.

Good wear-resistance: the Moh's hardness is up to 9.0, which helps to prolong the service life of mineral powder conveying equipment in mining, coal and other industries.

Good corrosion resistance: it's widely applied to different pipelines to form lined ceramic corundum layer, and has the features of acid-base resistance and fouling resistance.

Good temperature resistance and good heat shock resistance: the products have good thermal stability and could be used for a long time in the professional environment with temperature lower than 800 degree centigrade.

Low use cost: the ceramic lined steel pipes are cheap and connected with welded flanges. The engineer cost of the products is low but the service life is long.

Convenient for installation and construction: the pipe is light, and the flange is convenient for connection and installation, all of which reduce the installation cost.

We can produce and custom the different shape alumina ceramic tubes

Alumina T-shape tube

Alumina Y-shape tube

Alumina three way tube

Alumina straight tube

Alumina cone tube

Ceramic Lined Elbows/Bend

We have different sizes and mould for alumina ceramic tubes

1.ID45mm

2.ID112mm

3.ID59mm

4.ID126mm

5.ID134mm

6.ID75mm

7.ID95mm

8.ID150mm

Chemshun Ceramics advantage:

We can afford the standard and pre-engineered tiles;

We can afford the fabricated and lined equipment (finished product) according to customer requirement.

We have professional technical team to afford the CAD design drawings and develop new products for the pre-engineered tiles.

We have professional installation team to afford install service.

We have good process as per international standards.

We can offer 95% alumina ceramic wear-resistant products and grinding balls can be used in dry grinding environment.

We can decrease stream-to-stream time for users and reduce the cost of devices maintenance.

We can give you the lower price than inernational counterparts, and the delivery time is shorter than theirs.

We can be responsible for each cargo, and we are strict with quality control.

We can offer free samples to let our customer experience it first.

We can give you discounts when your quantity is bigger.

We can visit our customers regularly and talk with them in time if there is any problem.

We can contact our customers when we have new development.

Chemshun Ceramics wear-resistant product feature:

- Excellent wear and abrasion protection property.

- Excellent corrosion resistance property

- Excellent heat resistance property

- Excellent impact resistance property

- Excellent for ballistic protection

- high hardness

- light weight

- adhesive firmly

- high temperature resistance

- low cost

Chemshun Ceramics wear-resistant product application industries:

- Mining

- Mineral processing (mineral beneficiation)

- Power generation

- Cement

- Petro-Chemical Refining and Production

- Coal washery

- Steel

- Defense (personal & vehicle armour).

Common items equipment need wear linings are:

Agitators; Bends; Branches; Chutes; Classifiers; Cones; Cyclones; Distribution Box; Ejectors; Fans; Feeders; Hopper; Launders; Manifolds; Mills; Orifice; Pipes; Pipe Bends; Pipe fitting; Pulley lagging; Silos; Splitter Boxes; Spoons; Square Bends; Square to Round; Tanks; Troughs; Transfer points; T-Pieces; Y-Pieces etc.

We can supply you all kind of standard and customized ceramic products. Once you have any inquiry or need any product from us please feel free contact us.

Welcome you to visit our factory!

| Performance Index | 92 series | 95series |

| Al2O3 (%) | ≥ 92 | ≥ 95 |

| Moh' s Hardness | 9 | 9 |

| Water Absorption Rate(%) | < 0.01 | < 0.01 |

| Flexural strength, 20C, Mpa | 275 | 290 |

Bending

strengh(Mpa) | 255 | 275 |

| Bulk density(g/cm 3 ) | ≥ 3.60 | ≥ 3.65 |

Pingxiang Chemshun ceramics Co., Ltd is a professional manufacturer of 95% & 92% Al2O3 alumina wear ceramic products. Chemshun ceramics was established in 2002, we have 15 years of professional ceramic producing and import & exporting experierence. Chemshun have the products and service of: Design, produce, sell, as follows:

1) 95% Al2O3 Alumina wear resistant product and high quality grinding media.

(we also can supply the Al2O3: 92% products according to detailed requirement):

Wear resistance Ceramic liner, alumina plaiin tile, ceramic weldable plate, alumina pipe, ceramic blocks, abrasion resistant lining, lined pipe and fitting, ceramic linings, wear-resistance ceramic linings, chemshun pre-engineered equipment lined ceramics and paiting, custom designed alumina ceramic, hexagonal ceramics sheet, square ceramic lining pieces, ceramic liner, Ceramic Conveyor Pulley Lagging, ceramic tube and all kind of engineered ceramics, the finished equipment according to drawings. Ceramic Grinding balls, griding cylinders. Products used in the mineral, steel, power, port, cement, ceramic, glass etc industries, and was fixed on the equipment of chute, cyclone, cone, fan etc. We not only afford the products but also can afford the engineer service and on-site fixing.

2)High quality Catalyst support media /support covering materials (Inert ceramic balls, 99 alumina balls, all kind of ceramic/alumina rings) and all kinds of tower packings(Mat: Eramic/Plastic/Metallic), saddles, pall rings, flower rings, raschig rings, cascade mini rings etc) and ceramic honeycomb products.

Aim for servicing with the global maket, we established a new factory in 2008 which mainly supplys the high alumina wear resistant product and the high quality catalyst support media. With the predominance be of honesty, efficiency, specialty and innovation, Pingxiang chemshun ceramics Co., Ltd will satisfy global makket requirement.

Has strong research and production capability, with an annual production capacity of 4000 tons of wear-resistance product (grinding balls & lining bricks, alumina plate, alumina mosaic product), 1500m3 catatalyst support /covering materials (inert ceramic balls, 99alumina balls, ceramic honeycomb materials) and 1500m3 various chemical packing. We aim to serve clients from all over the world.