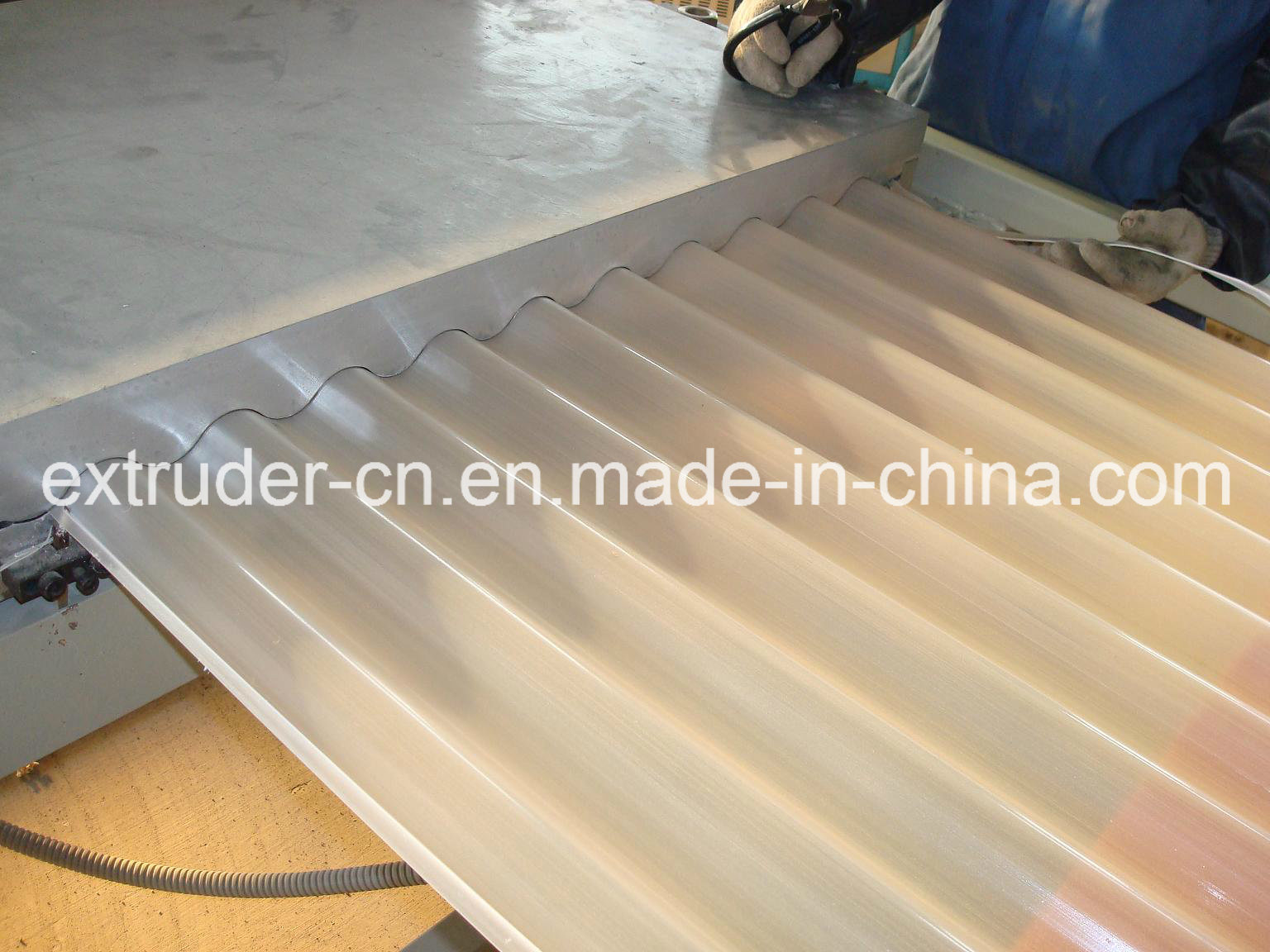

Wave plate has an excellent corrosion resistance, weather resistance, easy processing, low cost and many other characteristicsm abd is widely used for roof material of workshops, warehouses.

Production line consists of:

Extruder: Single-screw extruder PP / PE / PC, conical twin-screw extruder PVC.

T die head: The hanger-type flow structure, a suitable compression ratio to ensure the stability of material flow evenly.

Calibrating molds: Rational design, the unique design of the cooling flow to ensure the accuracy of products,

Hauling machine: Roller traction, using high quality NBR rubber roller, pneumatic adjustment, and frequency speed adjustment.

Cutting Machine: Knife cutting, fast, good accuracy.

Extrusion Line Type SJSZ-65/132 for PVC Single Layer Corrugated Sheet, Including:

1 Set of Twin Screw Extruder SJSZ-65/132 1 Set of Die Head 1 Set of Guide Roller 1 Set of Accessory Equipments for PVC Corrugated Sheet, Calibrating Unit, Edge Cutting Device, Hauling Machine, Knife Cutting Machine and Stacker. 2.1. Twin Screw Extruder SJSZ-65/132

| Item | Description | Unit | SJSZ65/132 | | 1 | Output Capacity | Kg/h | Max.250 | | 2 | Number of the Screws |

| 2 | | 3 | Diameter of the Screw | mm | 65/132 | | 4 | Rotating Direction of the Screws |

| Forth & Reverse | | 5 | Rotation Speed of the Screw | r/min | 1-34.7 | | 6 | Available Working Length of the Screws | mm | 1430 | | 7 | Main Motor Power | Kw | 37 | | 8 | Speed Adjusting Mode |

| frequency conversion adjustable, Invertor from OMRON | | 9 | Gear Reducer |

| Rigid-gear surface low noise design | | 10 | Heating Capacity of the Screw barrel | Kw | 24 ( casting-aluminium electric-thermal elements ) | | 11 | Material of the Screws and the barrel |

| 38CrMoALA | | 12 | Nitriding Depth of the Screws and the barrel | mm | 0.5~0.7 | | 13 | Nitriding Rigidity of the Screws and the Barrel | HRC | 50~55 | | 14 | Cooling Mode of the Screw barrel |

| by air cooling | | 15 | Temperature Adjustment of the Screws |

| By Screw-core Temperature Adjusting Device | | 16 | Indicators |

| Melt pressure & temperature indication by gauge | | 17 | Temperature Controllor |

| Brand: Omron, Japan | | 18 | Element of Electric System ( contactors, buttons, switches ) |

| Brand: Schneider | | 19 | Power of the Vacuum Pump | Kw | 1.5 | | 20 | Max. Vacuum Degree | MPa | -0.093 | | 21 | Cooling Water Consumption | L/min | 1~3 | | 22 | Plastic Material Feeding Mode |

| By Fixed-quantity Screw

Feeding Device | | 23 | Rotation Speed of the Feeding Screw | R/min | 3.5~47 ( frequency conversion ) | | 24 | Height of the Screw Axes | mm | 1000 | | 25 | Figure Dimensions ( L×W×H ) | mm | 4235×1520×2450 | | 26 | Weight | Kg | 4000 |

2.2. Die Head, 1 set

| Item | Description | Unit | 1200mm | | 1 | Die head width | mm | 1200 | | 2 | Adjusted thickness | mm | 0.75-0.8 |

2.3. Guide Roller, 1 set

| Item | Description | Unit | 800mm | | 1 | Quantity of the roller |

| 2 | | 2 | Diameter of the roller | mm | 200 | | 3 | Width of the roller | mm | 1250mm | | 4 | Cooling Method |

| Internal Cooling |

2.4. Accessory equipments for PVC corrugated sheet, calibrating unit, edge cutting device, hauling machine, knife cutting machine and stacker. 1 set

2.4.1 . Calibrating Unit

| Item | Description | Unit | DX-1000 | | 1 | Calibrating mould width | mm | 800 | | 2 | Material of mould |

| 40Cr | | 3 | Length | mm | 500 | | 4 | Clamping method |

| Pneumatic | | 5 | Water pump power | KW | 3 |

2.4.2 Edge Cutting Device

2.4.3 . Hauling-off Machine

| Item | Description | Unit | 1000mm | | 1 | Diameter of rubber roll | mm | 220 | | 2 | Width of rubber rolls | mm | 800 | | 3 | Clamping method |

| Pneumatic | | 4 | Driving motor | kw | AC, 2.2KW, OMRON inverter | | 5 | Hauling speed | m/min | 0.5-4.5 |

2.4.4 . Knife C utting M achine

| Item | Description | Unit | 1000mm | | 1 | Method |

| Knife Cutting | | 2 | Cutting width | mm | 800 | | 3 | Cutting thickness | mm | 1.2 | | 4 | Driving method |

| Electric | | 5 | Length counter |

| Digital | | 6 | Cutting Length | mm | 2500( Adjustable) |

2.4.5 . Stacker

| Item | Description | Unit |

| | 1 | Material of working table |

| Stainless steel | | 2 | Working length |

| 6000 |

|

Qingdao Leader Machinery Co., Ltd is an experienced and professional manufacturer of plastic extruder and extrusion lines for years. We can produce various equipments, including plastic pipe extrusion lines, plastic profile extrusion lines, plastic sheet/plate extrusion lines and also some recycling and pelletizing machines etc. According to different requirement s of each customer, our engineers will provide most professional mechanical design and manufacturing, and the complete processing technology to meet their special application requirements.

Since foundation, we have been dedicated to study and research new products, new processing technology to satisfy the updating requirements of the world, and also we continuously digest and learn from the world advanced science technology and leading process. We are always standing firm ahead domestically in the plastic-extruder field as the pioneering representative. With years of experience in design and fabrication, we newly developed LM series extrusion lines, which realized the high efficiency extrusion idea "high precision control, high efficiency production, high quality production".

Through ISO9001-2008 quality certification, CE certification, SGS certification and GOST certification for Commonwealth of Independent States, strict following the standards of modern enterprise, the overall strengthening and the effective management of production, procurement, technology, and after sale service. We win the market by high quality products and services. At present, products have been exported to the US, Korea, Russia, Ukraine, Kazakhstan, Hungary, UAE, Turkey, Iran, Saudi Arabia, South Africa, Libya, Algeria, India, Nepal, Bangladesh, Mexico, Argentina, Chile and other countries and regions, praised by customers.