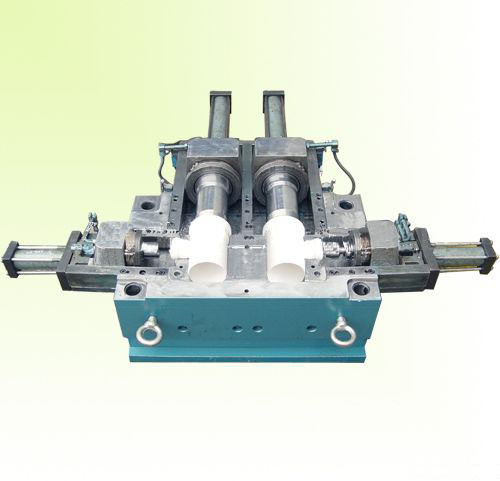

Features of PVC Pipe fitting molds

PVC pipe fitting Mould ( for high pressure and low pressure = for water supplying and water discharging)

* CPVC pipe fitting mould for high pressure

* UPVC pipe fitting mould for water drainage

* PVC belling pipe fitting mould( with collapsible cores for pressure water supply).

* Electricity cable pipe fitting mould, built in-wall various PVC pipe fittings.

The technical solutions for PVC pipe fitting moulding and PVC pipe fitting mould manufacturing. PVC is a kind of special material which need special injection molding process. The basic feature of PVC material:

* Hard PVC material low MFI

* PVC with high corrosive

* PVC with low temperature melting

* Easy decomposition

Because of above basic features, PVC material has special molding process. The injection molding machine need precise temperature controlling and the material can not be heated for a long time. We can say it is very sensitive with the temperature. Also for this reason, there is no PVC pipe fitting mold which can use hot runner system.

Because PVC material's high corrosive, PVC pipe fitting mould must need the steel be high quality stainless steel, and also deep hardened to around HRC50. Since the low MFI, when you make the runner and injection gate of a PVC pipe fitting mould, we need special design. For the big volume PVC injection molding, some time we need a very big runner and injection gate. But the runner can't be recycled, what should we do? I think the only way is to reduce the runner flowing distance to reduce the runner waste

-----------------CPVCPipe fittings molds------------------

CPVC fitting moulding size from 25mm up to 160mm diameter

CPVC fitting type: Coupler, TEE, Reducer, Elbow, Cross, End cap, Socket

CPVC fitting mould cavity No.: From single cavity to 32 cavities CPVC fitting mold

CPVCfitting mould cavity and core steel: DIN 1.2316 stainless made by Thyssen Krup German. Tempered with HRC 48

Cooling: Optimal cooling effections, with moldmax adaption available

Stroke switch for slide action safety and prolong the CPVC fitting mould life

-----------------UPVCPipe fittings molds------------------

UPVC fitting moulding size from 25mm up to 160mm diameter

UPVC fitting type: Coupler, TEE, Reducer, Elbow, Cross, End cap, Socket

UPVC fitting mould cavity No.: From single cavity to 32 cavities UPVC fitting mould

UPVC fitting mould cavity and core steel: DIN 1.2316 stainless made by Thyssen Krup German. Tempered with HRC 48

Cooling: Optimal cooling effections, with moldmax adaption available

Stroke switch for slide action saftey and prolong the UPVC fitting mould life

Shanghai Guangsu Plastics Manufacture Co., Ltd., locates in Shanghai Songjiang Hi-tech Park, covering an area of 238 mu. As situated at the exit Dagang near HuHang Highway and TongSan Highway, as well as neighboring Shanghai University City and the terminal station of Shanghai Metro Line 9---Songjiang New City Station, It enjoys very convenient transportation.

Having consistently adhered to the operation concept of "Excellent Products, Star-grade Service", the plastic injection machine of "Guangsu" brand is well popular in plastic machinery industry by its advantages of high quality, high efficiency and energy saving etc. The main products of the company include GM series plastic injection machine with constant-flow pump, HS series energy-saving plastic injection machine with servo-motor GSV series variable energy-saving plastic injection machine and other plastic injection machines of more than 40 specifications as well as relevant auxiliary machines and molds, with its range covering from 50t to 2000t, and the injection amount from 30g to 10000g. At same time, the company has rich experience and excellent cooperation suppliers for peripheral equipments of plastic formation products.

The annual output of plastic injection machine reaches up to over 3200sets, with its sales network covering all over the country. The products are also exported to more than 50 countries and regions in Europe, Central America, Middle East, South East Asia and Africa, such as Russia, USA, Romania, Turkey, India, Syria, Iran, Burma, Nigeria, and Cameroon. Meanwhile, in order to be adapted to the product processing demand of various industries, the company has developed the permanent suppliers for auxiliary equipments of plastic processing and mould processing manufacturers for the purpose of satisfying the processing demand for all kinds of products. The company has fully introduced the advanced CNC processing center from abroad to ensure the excellent quality of Guangming plastic injection machinery. The company has also taken the lead in the industry to pass the attestation of ISO9001-2000 quality management system standard and CE certification.

Following the principle of "Technology oriented, Management innovation, Quality first and Customer uttermost", the company has continued to enhance the development force, focusing on the development of a series of products with leading level at home and surpassing the international level, to make it become the new highlight for economic growth of the company. At same time, the company has introduced a series of new measures in the aspect of management and quality control, strengthened the collaboration with the domestic and international scientific research institutes and famous enterprise, creating carefully the brand "Guangsu" and improving the customer satisfaction. Under the leadership of the company, all the staffs have decided to carry on the spirit of "Union, Struggle, Practical, Devotion, Innovation and Development" to build the company as a first class famous enterprise. We'd like to give our sincere thanks to the friends from all circles for their support and care. We welcome the presence of all kinds of customers!

Guangsu machinery, molds the brilliant future. We welcome all domestic and international customers to visit us and give us instructions. We will spare no efforts to provide our customers the more overall, professional and considerate service, to gain the confidence and support from both the old and new customers.