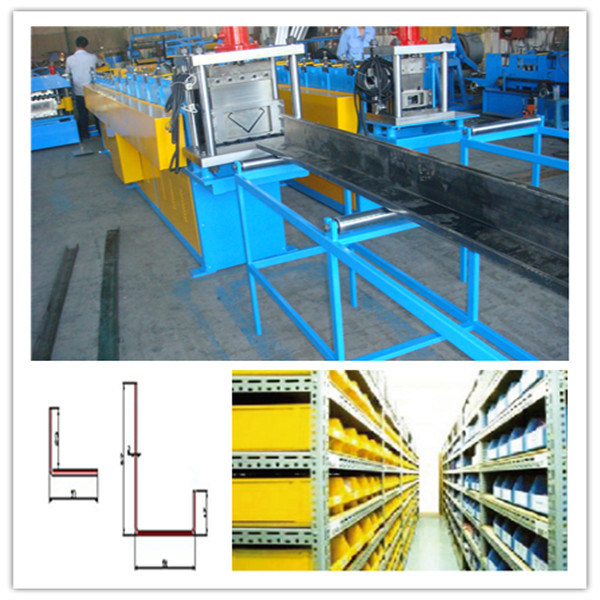

Storage Rack Forming Machine

Machine parts list

1.3t hydraulic un-coiler1 set

2. Leveling device1 set

3. Servo feeding device 1 unit

4. Press machine (including punching mould 7 sets)1 unit

5. Main roll forming machine1 set

6. Cassette5 units

7. Cutting holder1 set

8. Cutting blades7 sets

9. Hydraulic station1 set

10. Control system ( including control box)1 set

11. Out tables2 units

12. Spare parts1 package

Technique data

1. Decoiler

Diameter: 460-520mm expansion

Expansion: Hydraulic

Capacity: 3000kg per mandrel

Max Coil Width: 500mm

Drag tension brake with variable brake tension adjustment valve

2. Leveling device

7 rolls leveling, 3 rolls up and 4 rolls down

Diameter is Ø 80mm, chrome and HRC60 heat treatment to secure the smooth surface

Leveling Raw Material thickness: 1.5-2.0mm

Max Leveling Raw Material width: 300mm

3. Feeding device

Feeding Servo feeding motor: 1.3KW, Yaskawa(Japanese Brand)

Description: Servo feeding can control the punching distance in precision, controlled by PLC, and the feeding tolerance can be+-0.05mm, the servo motor can control the speed, and can accept the input signal, and react quickly, and performance well, the touch screen can display the rotating speed, the length and the quantity, it can be controlled by the manual and auto modes.

4. Press machine

5. Main roll forming machine technique data

5.1. Suitable Plate Material: Thickness 1.5-2.0mm, Galvanized steel or blank steel

5.2. Working Speed: 12-15 meters / min

5.3. Forming Steps: According to different profiles, changing by 5 sets of cassettes

5.4. Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

5.5. Material of Shaft: 45# Advanced Steel (Diameter: 76mm), thermal refining

5.6. Driven system: Chain Driven 1.5 inches 20A

5.7. Main Power with reducer: 11KW WH Chinese Famous

5.8. Cutting: Hydraulic Cutting Cr12MOV

5.9. Material of Cutting Knife: Cr12MOV, Quench HRC58-62

5.10. Hydraulic Station Power: 5.5KW Wuxi Wanshen Famous Chinese Brand

5.11. The whole machine is controlled by industry computer-PLC.

5.12 PLC--Panasonic, Japan

5.13 Touch Screen--Panasonic Japan

5.14 Encoder--Omron, Japan

5.15 Electric parts--Schneider

Wuxi Suhang Machinery Manufacturing Co., Ltd. is a comprehensive enterprise combining production, sales and services. We are mainly engaged in providing machineries and equipments.

Owing to a professional teamwork, we are experienced in manufacturing, import and export, customers' design, installation and test, technical solution and after-sale services. We have shipped out our machines to more than 70 countries, and keep good business relationships with a large amount of worthy customers, contributing to our great business records and reputation.

We have our customers in different districts and continents. We sell products in the Middle East, Turkey, East Europe, Russia, South and East Asia and South America. Our factories are in Wuxi, which is just 100 km from Shanghai, just 45 min by the fast train. We have rich technology in design and manufacture for different requirements.

Our goal is to supply high quality products. We also try to guarantee timely delivery, all around services at reasonable cost. We have already established favorable relationships with many clients around the world. Working to extend our presence internationally, we are looking forward to cooperating with your company for mutual benefit. Please feel free to contact us.

Main product: C Purlin Roll Forming Machine; Z Purlin Roll Forming Machine; C/Z Iinterchangeable Purlin Roll Forming Machine Standing Seam Forming Machine; Bemo Sheet Forming Machine; Cold Roll Forming Machine; Roof Deck Forming Machine; Floor Deck Forming Machine; Guardrail Forming Machine; Glazed Tile Forming Machine; Corrugated Forming Machine; Double Layer Forming Machine; K Span Forming Machine; Hat Purlin Forming Machine; Hydraulic Curving Machine; Roller Shutter Production Line; Garage Door Production Line; Tapered Sheet Forming Machine, welcome to visit our factory!